IoT solutions and IT systems are strategic areas for companies in the coming years

Industrial companies have been at the forefront of technological innovation for years: both on the shop floor and in the field, robotics and machine parks are at an increasingly advanced level. However, there is a perceived gap between operational technologies and business-oriented information technology (IT). Until now, industries have lagged behind in the level of investment in IT. This trend is gradually changing, as companies in this sector start to invest more and more in digital transformation.

Survey „Readiness of Polish manufacturing companies for digital transformation and migration to the cloud. Situation Analysis in the Face of the COVID-19 Pandemic”, conducted by PMR on behalf of Dassault Systèmes shows that companies are increasingly aware of the potential of digital technologies in creating a new digital business model.

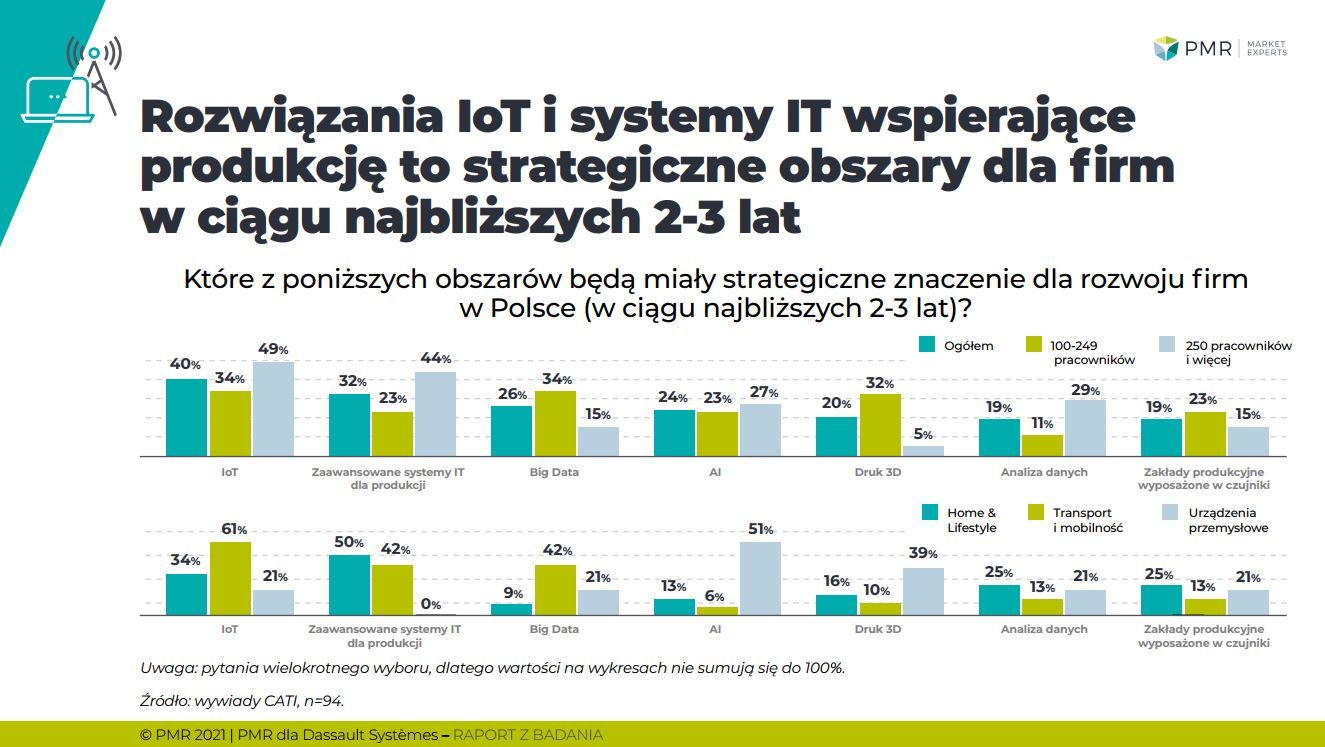

IoT and IT systems supporting manufacturing as strategic areas

In the conducted survey, the surveyed companies indicate IoT solutions and IT systems supporting manufacturing as strategic areas for companies in the next 2-3 years. While one in four surveyed entities also pointed to Big Data and artificial intelligence (AI) solutions as solutions that will have a significant impact on the market in the coming years.

The survey shows various areas of strategic importance for individual sectors: for 51% of manufacturers from the industrial equipment sector artificial intelligence is of key importance, while as many as 61% of companies from the transport and mobility sector stated that IoT will have by far the most significant impact on the market in the future.

What influences the decision to implement innovative IT solutions?

Manufacturing companies indicated specific benefits brought by advanced IT solutions as the main factors influencing the decision to implement them. These are:

- Increased manufacturing efficiency (50%)

- Reduction of costs connected with production (45%)

- Gaining a competitive advantage (44%)

- Reducing lead times (44%)

- Opportunity for business development in new markets (19%)

In contrast, companies cited the following as the biggest barriers to implementing innovative IT solutions:

- Lack of sufficient financial resources (47%)

- Lack of conviction of employees/users of the system as to the validity of the implementation (40%)

- Lack of knowledge about the financial benefits of implementation (34%)

- Lack of qualified staff (33%)

- Lack of time to implement the project (20%)

- Fear of implementation failure (14%)

At the same time companies indicated that recommendations, competence of the implementation team, quality of service and the company’s experience in performing similar implementations were among the most important criteria determining the choice of software supplier.

Survey „Readiness of Polish manufacturing companies for digital transformation and migration to the cloud. Covid-19 pandemic situation analysis.” was conducted by PMR on behalf of Dassault Systèmes between September and November 2020. The quantitative survey was conducted on a random sample of 105 medium and large manufacturing companies in Poland from the sectors of Transport and Mobility, Industrial Equipment, Aviation and Home & Lifestyle. Surveyed were mid- and high-level managers responsible for IT areas in companies.